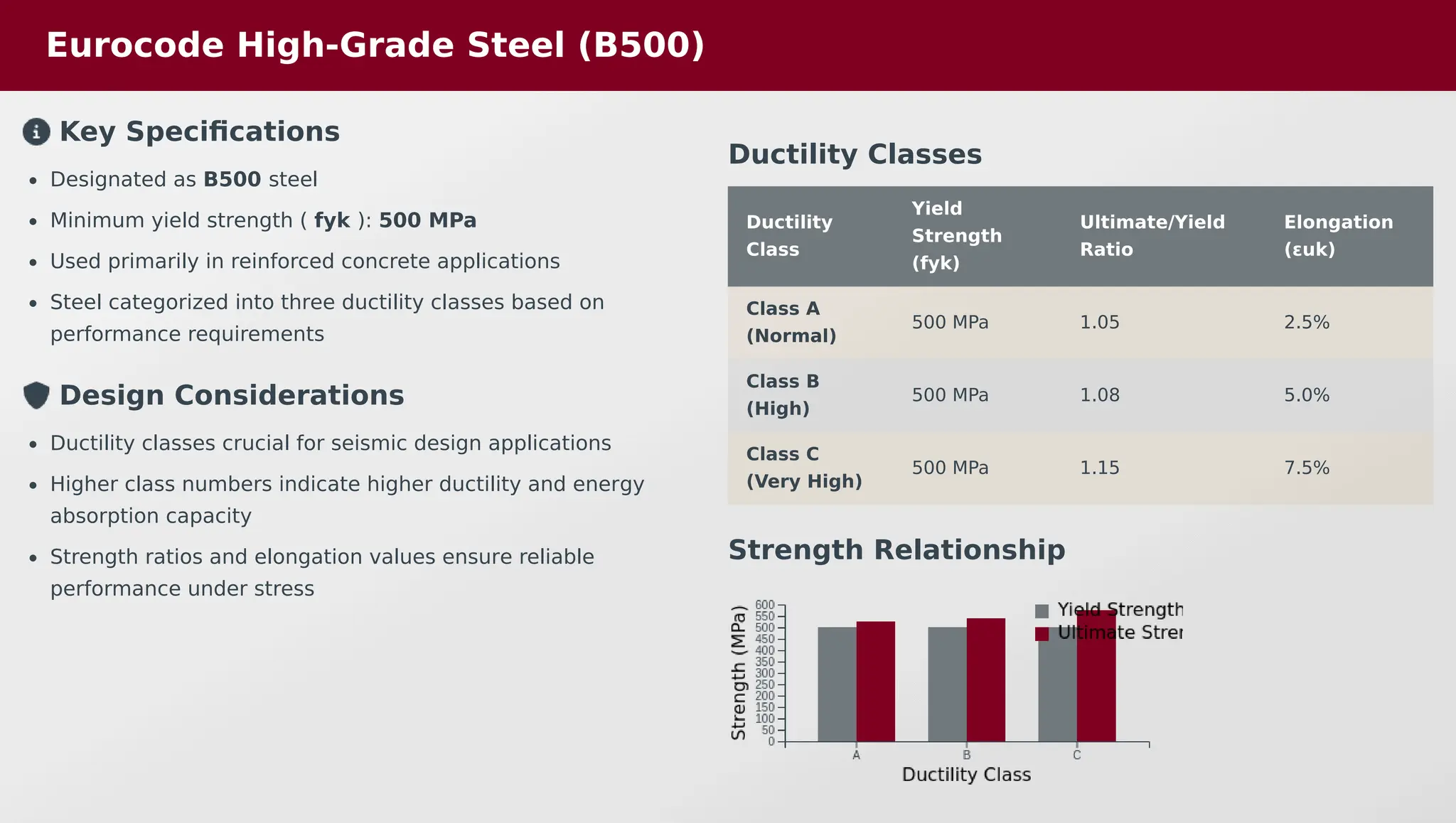

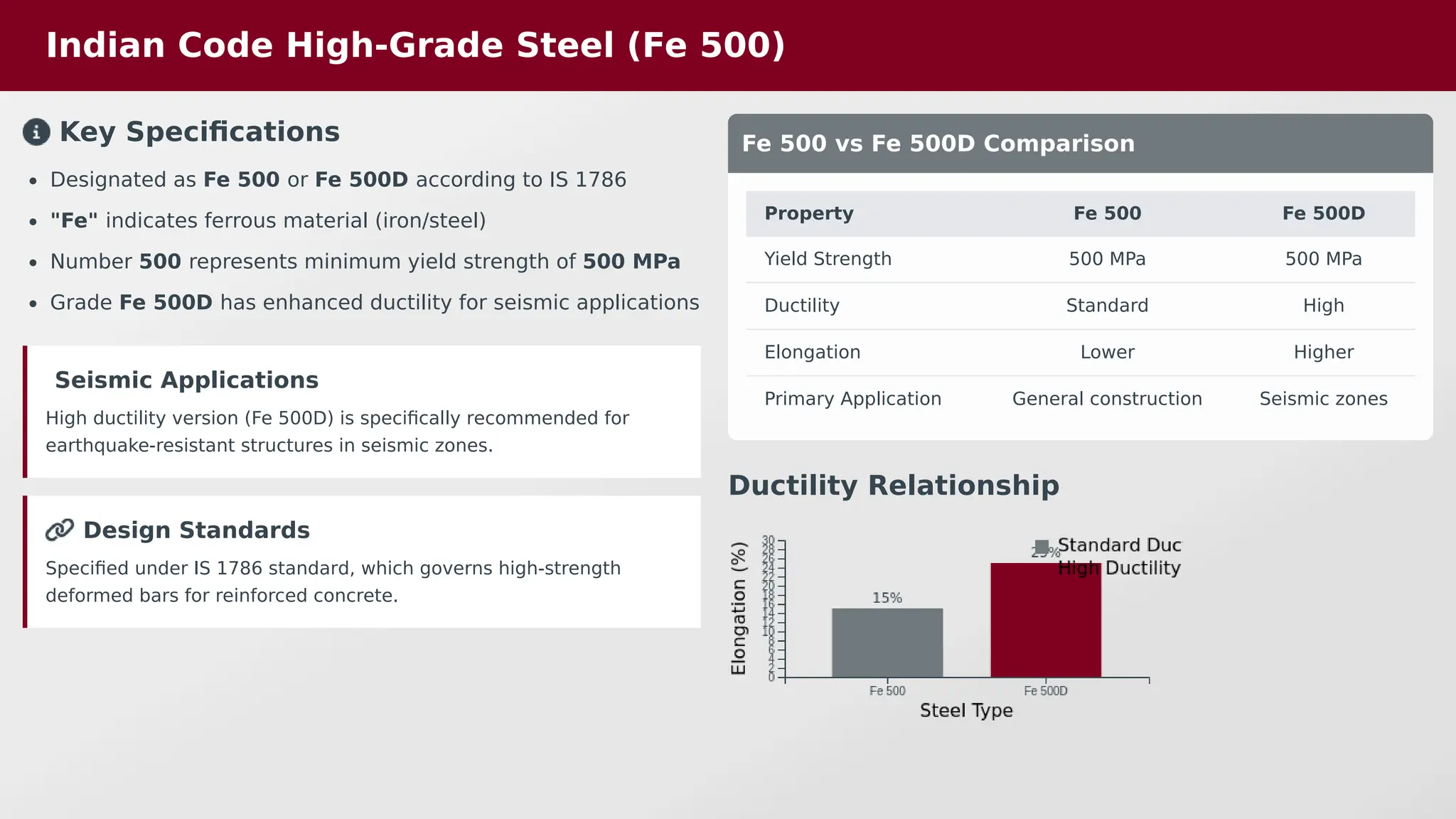

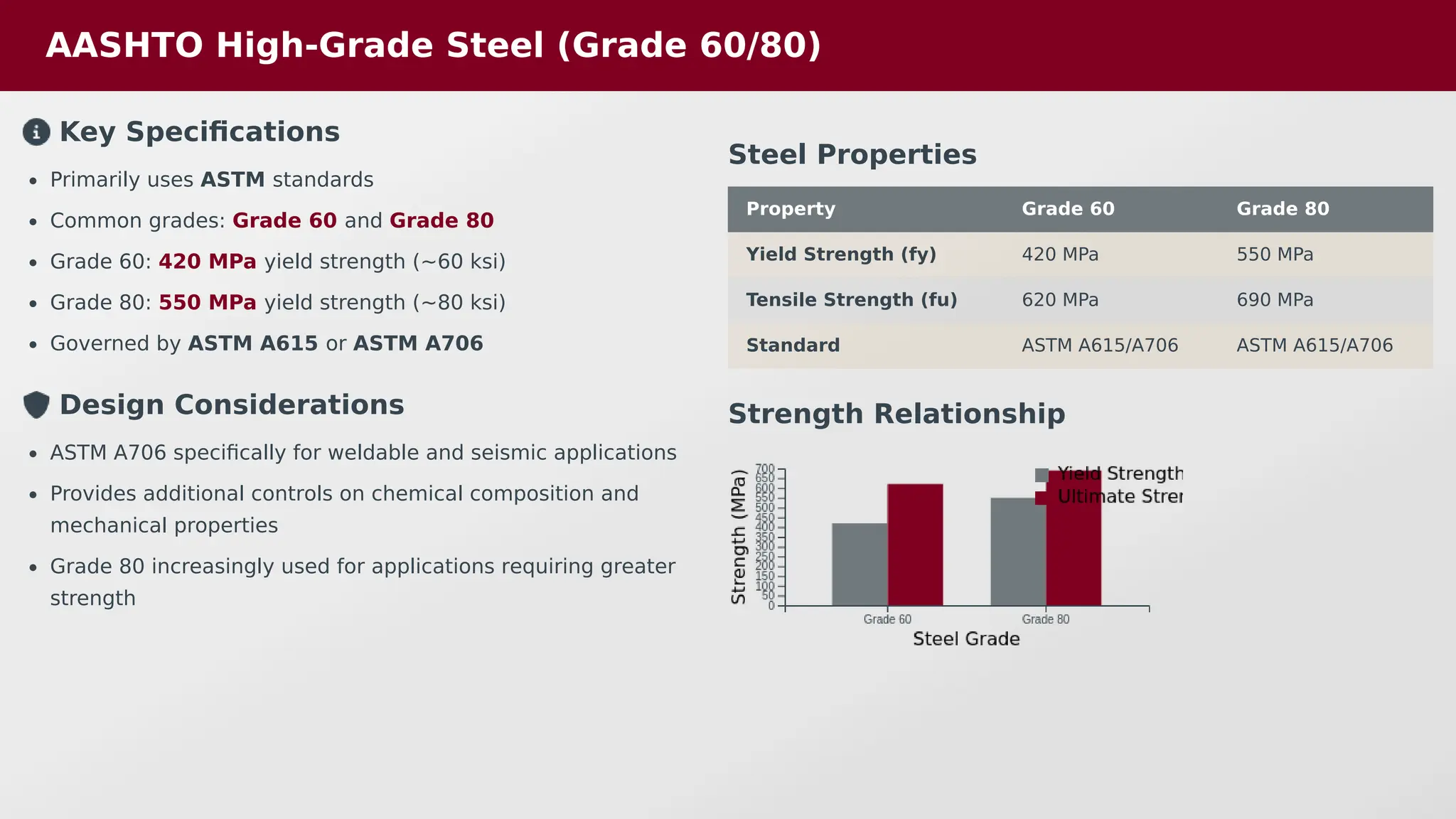

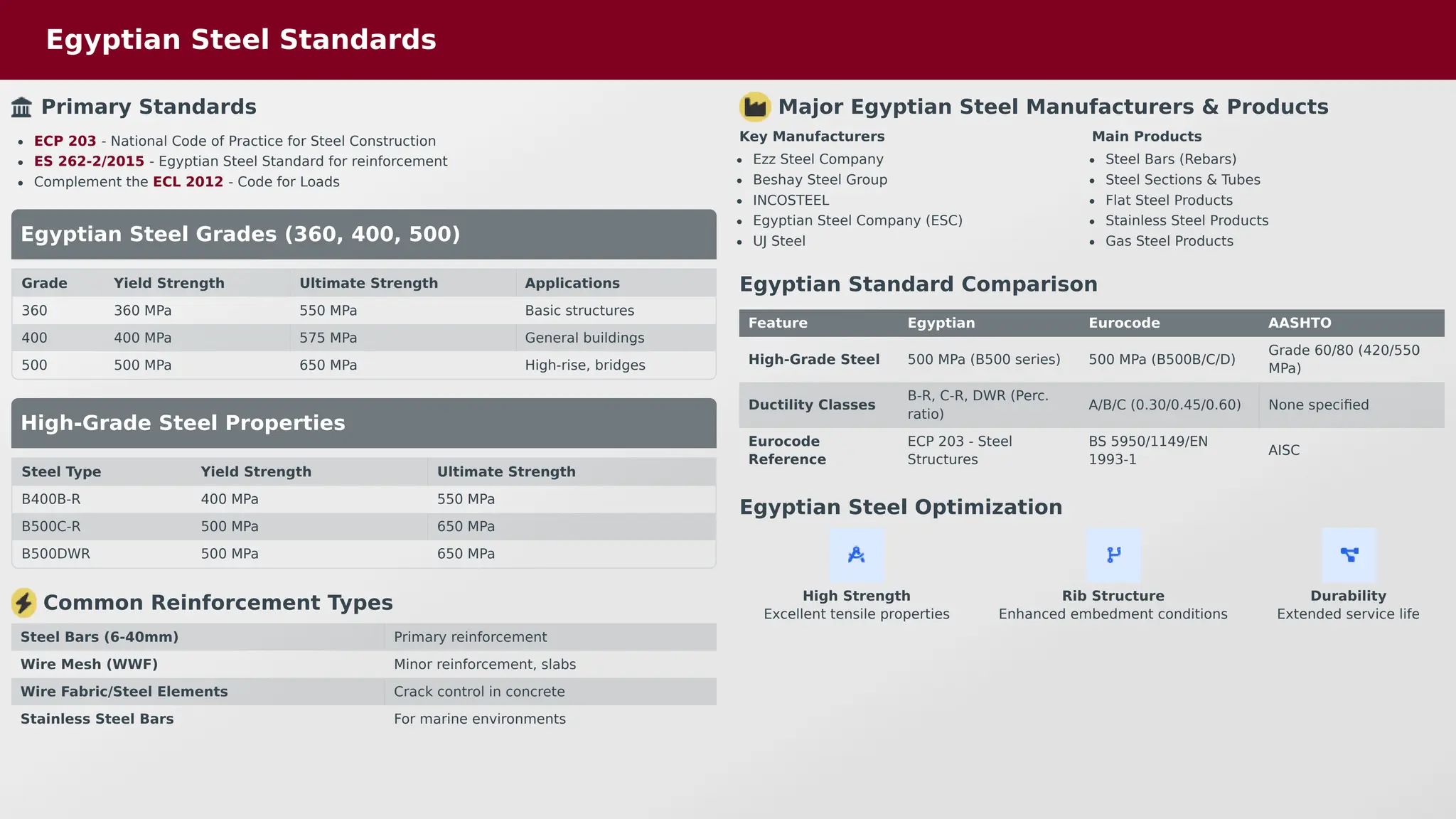

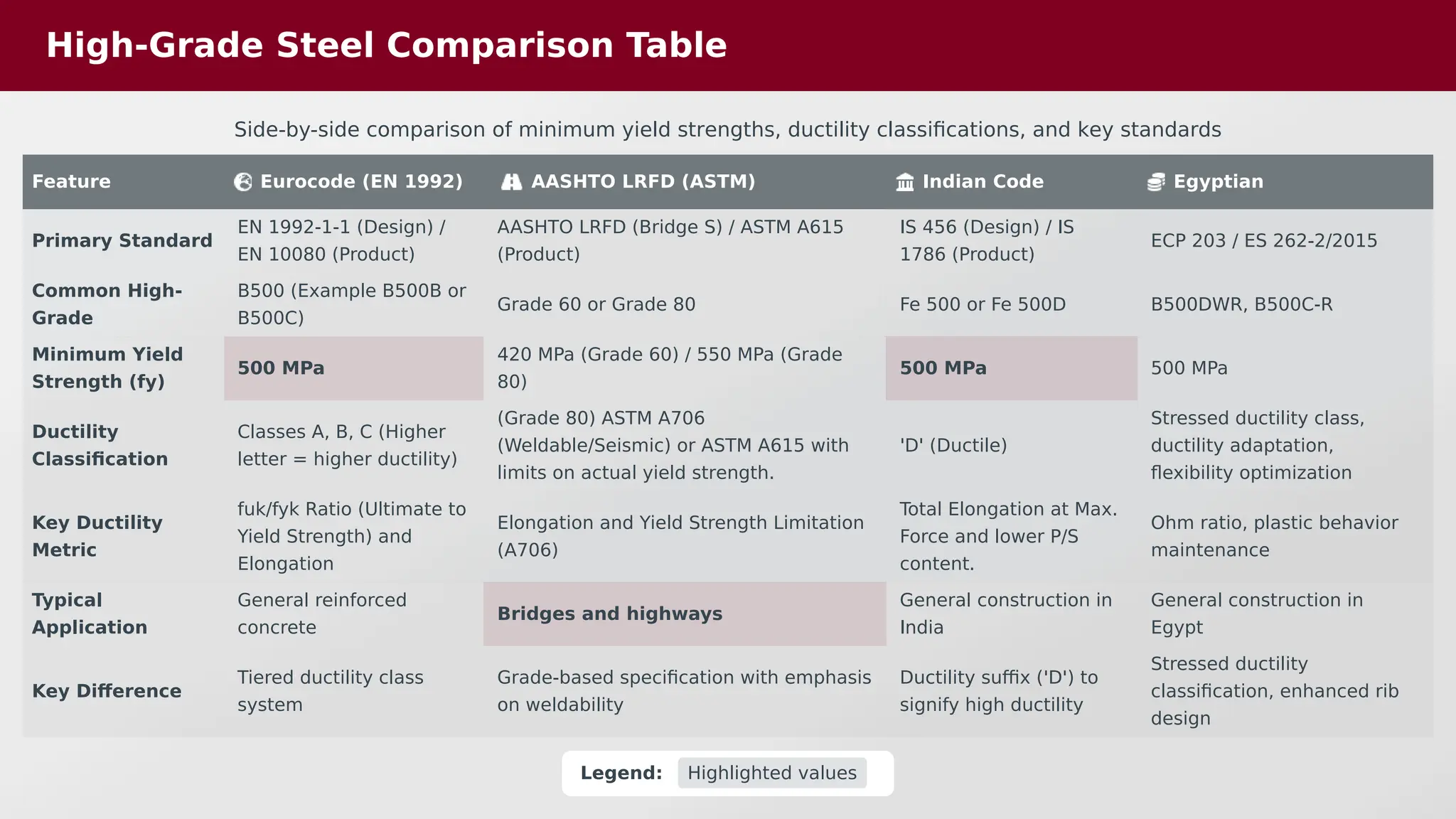

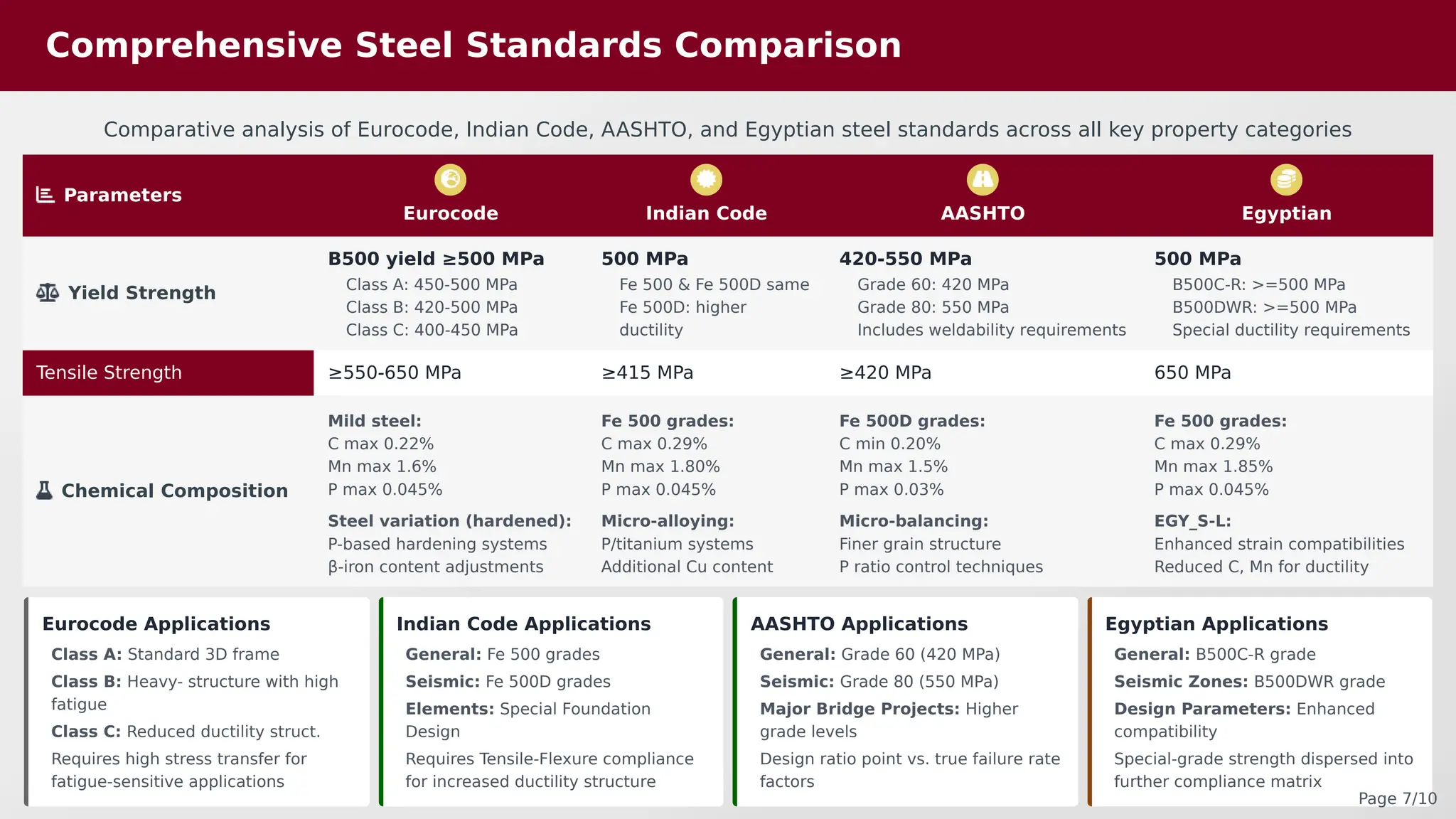

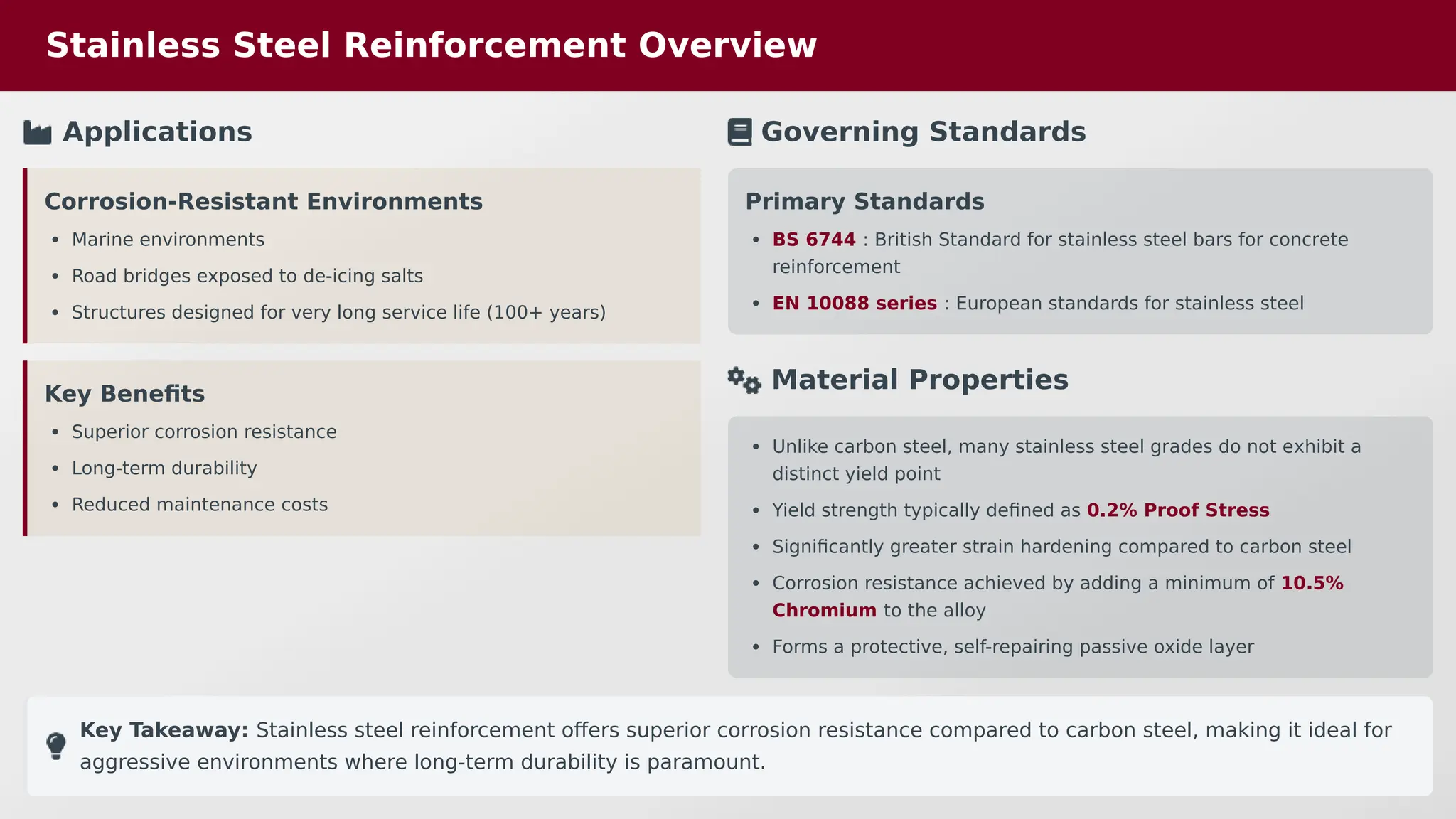

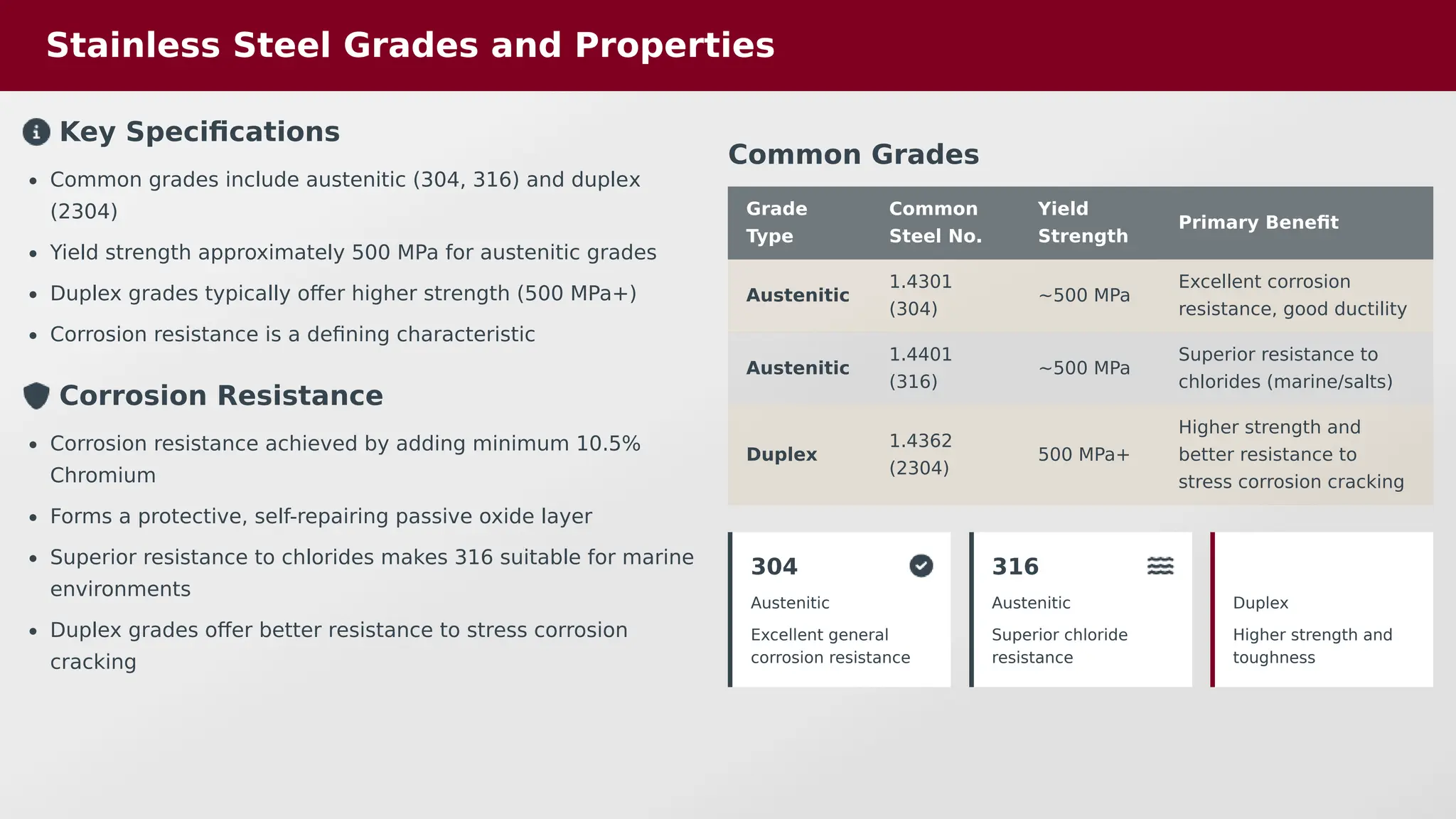

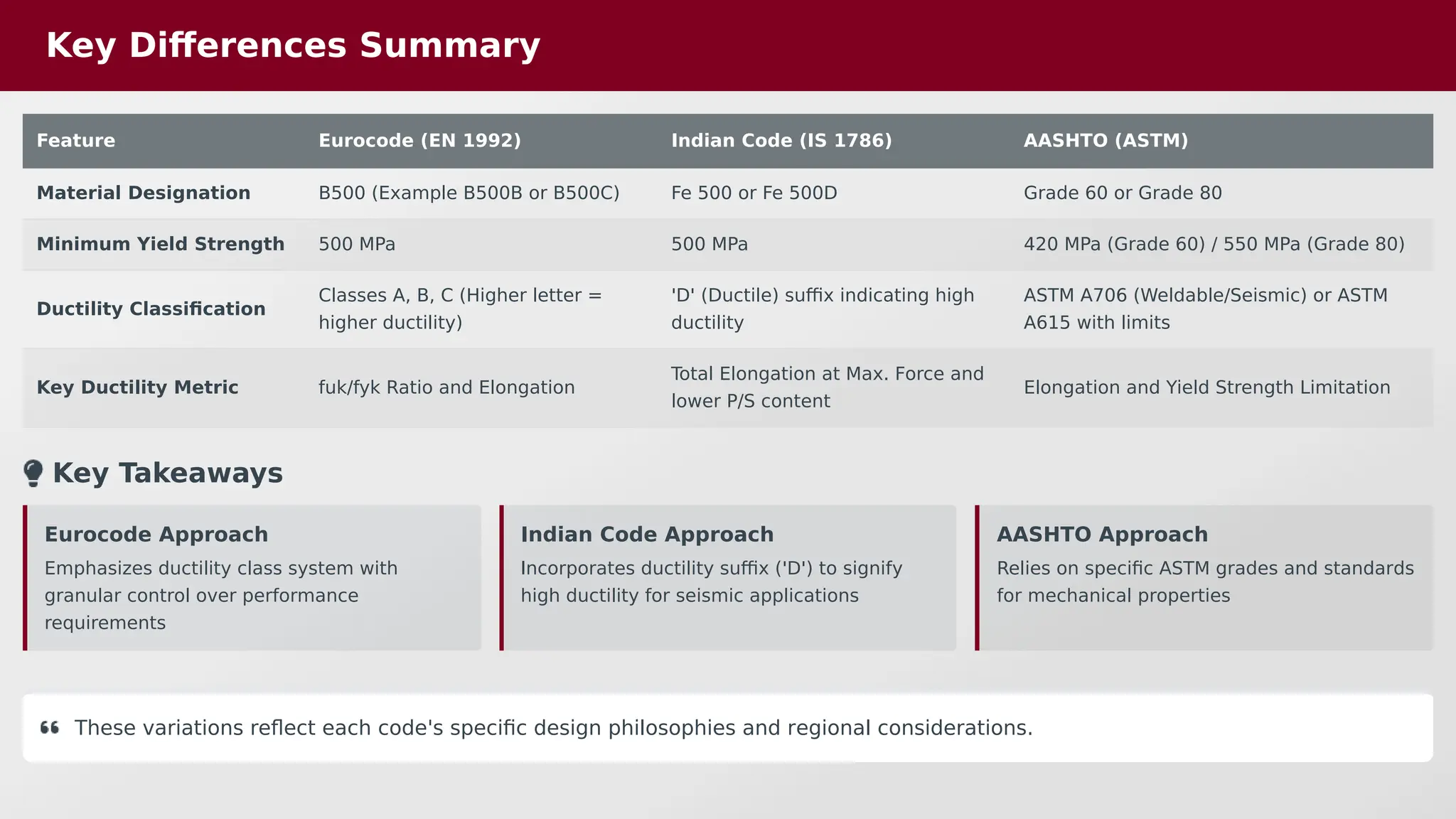

analysis comparing steel reinforcement standards across international codes. This comprehensive presentation examines the differences between Eurocode, Indian code, AASHTO code, and Egyptian standards for both high-grade steel and stainless steel reinforcement.